|

|

|

| Creep characteristics of fractured Beishan granite under the condition of multi-field coupling |

ZHANG Hai-Yang1,2( ), LIU Fei-Yang1,2, LIU Jian1,2 ), LIU Fei-Yang1,2, LIU Jian1,2 |

1. Beijing Research Institute of Uranium Geology, Beijing 100029, China

2. CAEA Innovation Center for Geological Disposal of High-Level Radioactive Waste,Beijing 100029, China |

|

|

|

|

Abstract After a disposal repository for high-level radioactive waste operates, the near-field surrounding rocks will be long in a thermal-hydrological-mechanical coupling environment. Therefore, their mechanical and permeability characteristics are crucial to the performance evaluation of the disposal repository. The surrounding rocks of the Beishan preselected area for the disposal of high-level radioactive waste in China are typical sparsely fractured granites, whose creep characteristics are directly related to the long-term safety of the disposal repository. Using water jet and wire cutting techniques, along with fracture surface blocking and combined sealing at rock sample ends, this study addressed the challenges of the sample preparation and sealing of fractured granite in thermal-hydrological-mechanical coupling triaxial tests. Based on this, multi-loading triaxial creep tests were conducted. The test results indicate that under the condition of multi-field coupling, the triaxial creep strength of the fractured granite was approximately 80% of its triaxial strength. Creep deformation increased with the axial load level, with lateral creeps more pronounced than axial creeps. For the compacted and crack propagation sections of the rock samples, both the axial strain rate and permeability decreased initially and then increased. In the case of consistent osmotic pressure difference, a higher osmotic water pressure within fractures would lead to decreased peak strength of the rock samples and result in greater lateral creep deformation.The results provide scientific support for the site selection, surrounding rock evaluation, engineering design and construction of the repository.

|

|

Received: 20 December 2023

Published: 08 January 2025

|

|

|

|

|

|

|

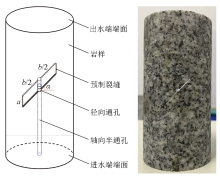

Schematic diagram of the rock sample with fracture

|

|

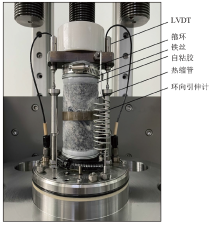

Sealing and installation of granite sample with single fracture for triaxial creep test

|

|

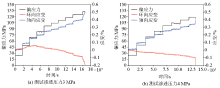

Relationship curves between deviatoric stress, strain and time in THM coupled triaxial creep test with different water pressures

|

|

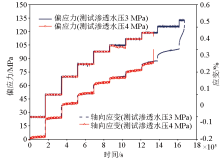

Comparison of axial deviatoric stress and strain versus time curves under different water pressures

|

|

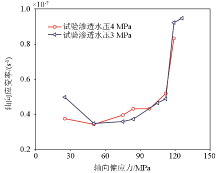

Axial strain rates at different loading levels under different water pressures

|

|

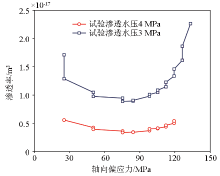

Comparison of permeability variation trends of rock samples under different water pressures

|

| [1] |

Rutqvist J, Freifeld B, Min K B, et al. Analysis of thermally induced changes in fractured rock permeability during 8 years of heating and cooling at the Yucca Mountain Drift Scale Test[J]. International Journal of Rock Mechanics and Mining Sciences, 2008, 45(8):1373-1389.

|

| [2] |

Souley M, Homand F, Pepa S, et al. Damage-induced permeability changes in granite:A case example at the URL in Canada[J]. International Journal of Rock Mechanics and Mining Sciences, 2001, 38(2):297-310.

|

| [3] |

欧阳蕊灿, 王卫军, 袁超. 考虑孔隙水压的岩体蠕变本构模型[J]. 矿业工程研究, 2022, 37(2):1-8.

|

| [3] |

Ouyang R C, Wang W J, Yuan C. On constitutive model of rock mass creep considering pore water pressure[J]. Mineral Engineering Research, 2022, 37(2):1-8.

|

| [4] |

杨红伟, 许江, 聂闻, 等. 渗流水压力分级加载岩石蠕变特性研究[J]. 岩土工程学报, 2015, 37(9):1613-1619.

|

| [4] |

Yang H W, Xu J, Nie W, et al. Experimental study on creep of rocks under step loading of seepage pressure[J]. Chinese Journal of Geotechnical Engineering, 2015, 37(9):1613-1619.

|

| [5] |

蒋海飞, 刘东燕, 黄伟, 等. 高围压下高孔隙水压对岩石蠕变特性的影响[J]. 煤炭学报, 2014, 39(7):1248-1256.

|

| [5] |

Jiang H F, Liu D Y, Huang W, et al. Influence of high pore water pressure on creep properties of rock under high confining pressure[J]. Journal of China Coal Society, 2014, 39(7):1248-1256.

|

| [6] |

刘德峰, 刘鹏涛, 张臻悦, 等. 轴压水压耦合作用下裂隙砂岩蠕变特性[J]. 工程科学与技术, 2021, 53(1):94-103.

|

| [6] |

Liu D F, Liu P T, Zhang Z Y, et al. Creep characteristics of fractured sandstone under the coupling action of axial compression and hydraulic pressure[J]. Advanced Engineering Sciences, 2021, 53(1):94-103.

|

| [7] |

陈英, 谢辉, 杨俊, 等. 真实水压作用下裂隙大理岩蠕变特性试验研究[J]. 工程科学与技术, 2021, 53(4):149-157.

|

| [7] |

Chen Y, Xie H, Yang J, et al. Experimental study on creep properties of fractured marble under water pressure[J]. Advanced Engineering Sciences, 2021, 53(4):149-157.

|

| [8] |

郭保华, 田采霞. 岩石裂隙的法向蠕变及渗流的影响[J]. 河南理工大学学报:自然科学版, 2012, 31(4):403-408.

|

| [8] |

Guo B H, Tian C X. Normal creep deformation law of rock fracture and the influence of seepage[J]. Journal of Henan Polytechnic University:Natural Science Edition, 2012, 31(4):403-408.

|

| [9] |

王辰霖, 郭保华. 大理岩裂隙渗流的时间效应试验研究[J]. 地下空间与工程学报, 2018, 14(6):1498-1504.

|

| [9] |

Wang C L, Guo B H. Experimental study on time effect of seepage properties of marble fracture[J]. Chinese Journal of Underground Space and Engineering, 2018, 14(6):1498-1504.

|

| [10] |

Park S, Kim J S, Kim G Y, et al. Evaluation of mechanical properties of KURT granite under simulated coupled condition of a geological repository[J]. Journal of Korean Tunnelling and Underground Space Association, 2019, 21(4):501-518.

|

| [11] |

Yang S Q, Xu P, Li Y B, et al. Experimental investigation on triaxial mechanical and permeability behavior of sandstone after exposure to different high temperature treatments[J]. Geothermics, 2017, 69:93-109.

|

| [12] |

Yang S Q, Hu B, Tian W L. Effect of high temperature damage on triaxial mechanical failure behavior of sandstone specimens containing a single fissure[J]. Engineering Fracture Mechanics, 2020, 233:107066.

|

| [13] |

江宗斌. 多场环境作用岩石蠕变特性试验及力学模型研究[D]. 大连: 大连海事大学, 2016.

|

| [13] |

Jiang Z B. Creep characteristics test and mechanical model study of rock under multi-field environmental action[D]. Dalian: Dalian Maritime University, 2016.

|

| [14] |

张培森, 赵成业, 侯季群, 等. 温度—应力—渗流耦合条件下红砂岩渗流特性试验研究[J]. 岩石力学与工程学报, 2020, 39(10):1957-1974.

|

| [14] |

Zhang P S, Zhao C Y, Hou J Q, et al. Experimental study on seepage characteristics of deep sandstone under temperature-stress-seepage coupling conditions[J]. Chinese Journal of Rock Mechanics and Engineering, 2020, 39(10):1957-1974.

|

| [15] |

Meng L B, Li T B, Xu J, et al. Deformation and failure mechanism of phyllite under the effects of THM coupling and unloading[J]. Journal of Mountain Science, 2012, 9(6):788-797.

|

| [16] |

胡波, 杨圣奇, 徐鹏, 等. 单裂隙砂岩蠕变模型参数时间尺度效应及颗粒流数值模拟研究[J]. 岩土工程学报, 2019, 41(5):864-873.

|

| [16] |

Hu B, Yang S Q, Xu P, et al. Time-scale effect of the creep model parameters and particle flow simulation of sandstone with a single crack[J]. Chinese Journal of Geotechnical Engineering, 2019, 41(5):864-873.

|

| [17] |

秦楠, 张作良, 冯学志, 等. 蠕变作用后裂隙类岩石单轴强度和裂纹扩展规律研究[J]. 煤炭科学技术, 2020, 48(12):244-249.

|

| [17] |

Qin N, Zhang Z L, Feng X Z, et al. Study on uniaxial strength and crack propagation law of cracked similar rock after creep[J]. Coal Science and Technology, 2020, 48(12):244-249.

|

| [18] |

梁冰, 张涛, 王俊光, 等. 裂隙辉绿岩蠕变试验及模型研究[J]. 实验力学, 2019, 34(2):351-357.

|

| [18] |

Liang B, Zhang T, Wang J G, et al. Creep experimental study and model improvement of fissured diabase[J]. Journal of Experimental Mechanics, 2019, 34(2):351-357.

|

| [19] |

张国朋. 岩石通透裂隙扩展机理及其蠕变特性研究[D]. 青岛: 山东科技大学, 2018.

|

| [19] |

Zhang G P. Study on cracks propagation mechanism and creep properties of fractured rock[D]. Qingdao: Shandong University of Science and Technology, 2018.

|

| [20] |

蒋海飞, 刘东燕, 赵宝云, 等. 高围压高水压条件下岩石非线性蠕变本构模型[J]. 采矿与安全工程学报, 2014, 31(2):284-291.

|

| [20] |

Jiang H F, Liu D Y, Zhao B Y, et al. Nonlinear creep constitutive model of rock under high confining pressure and high water pressure[J]. Journal of Mining & Safety Engineering, 2014, 31(2):284-291.

|

| [1] |

SHI Lei, GUAN Yao, FENG Jin, GAO Hui, QIU Xin-Wei, QUE Xiao-Ming. Multi-level division method of flow units for accurate permeability assessment of glutenite reservoirs:A case study of reservoir W53 of Paleogene Wenchang Formation in Lufeng oilfield[J]. Geophysical and Geochemical Exploration, 2022, 46(1): 78-86. |

| [2] |

REN Yi-fa, HU Jun, FAN Zhao-Ju, PENG Liu. BOREHOLE GEOCHEMICAL EXPLORATION OF THE LOW POROSITY AND LOW PERMEABILITY RESERVOIRS IN NORTHEAST YAOYINGTAI AREA[J]. Geophysical and Geochemical Exploration, 2006, 30(2): 129-132,140. |

|

|

|

|