|

|

|

| Tunnel-scale evaluation of rock mass suitability for the disposal of high-level radioactive waste |

YE Yong1,2( ), CHEN Liang1,2( ), CHEN Liang1,2( ), LIU Jian1,2 ), LIU Jian1,2 |

1. Beijing Research Institute of Uranium Geology, Beijing 100029, China

2. CAEA Innovation Center for Geological Disposal of High-Level Radioactive Waste, Beijing 100029, China |

|

|

|

|

Abstract Rock mass suitability evaluation is a core part of the siting and design of a disposal repository for high-level radioactive waste, aiming to determine whether the rock masses at the site meet the functional requirements for long-term containment and radionuclides isolation. Based on the previously proposed site-scale evaluation method (QHLW) of rock mass suitability, this study further developed criteria for the tunnel-scale evaluation of rock mass suitability and established a two-phase evaluation system consisting of pre-evaluation and final evaluation. Additionally, in combination with geological and hydrological data revealed by demonstration tunnel 1 (DT1) at the site of the ONKALO underground research laboratory in Finland, this study tested and verified the criteria of the two-phase evaluation system on the disposal tunnel scale. The comparison between the suitability evaluation results obtained using the optimized QHLW and the qualitative evaluation results determined using the rock suitability classification (RSC) rock mass grading method indicates that both methods yielded roughly consistent results. This confirms the feasibility of the tunnel-scale evaluation method of rock mass suitability.

|

|

Received: 21 December 2023

Published: 08 January 2025

|

|

|

|

|

|

| 处置罐体材料 | 地下水化学环境 | | | 铜 | 同时满足以下2个条件:(1)7<pH<10;(2)[SO42-]<[Cl-]<2 500 mg·L-1 | 1.0 | | 仅满足以下1个条件:(1)7<pH<10;(2)[SO42-]<[Cl-]<2 500 mg·L-1 | 0.8 | | 以下2个条件均不满足:(1)7<pH<10;(2)[SO42-]<[Cl-]<2 500 mg·L-1 | 0.1 | | 碳钢 | 同时满足以下2个条件:(1)8<pH<9.5;(2)[HCO3-]<6 000 mg·L-1且[Cl-]<3 000 mg·L-1 | 1.0 | | 仅满足以下1个条件:(1)8<pH<9.5;(2)[HCO3-]<6 000 mg·L-1且[Cl-]<3 000 mg·L-1 | 0.8 | | 以下2个条件均不满足:(1)8<pH<9.5;(2)[HCO3-]<6 000 mg·L-1且[Cl-]<3 000 mg·L-1 | 0.1 |

|

Scope of corrosion resistance coefficient of disposal canister

|

| 地下化学环境 | 取值 | | 同时满足以下3个条件:(1)6<pH<10;(2)TDS<10 g·L-1;3)I>10-3mol·L-1 | 1.0 | | 满足以下3个条件中的2个:(1)6<pH<10;(2)TDS<10 g·L-1;3)I>10-3mol·L-1 | 0.8 | | 仅能满足以下3个条件中的1个或均不满足:(1)6<pH<10;(2)TDS<10 g·L-1;3)I>10-3mol·L-1 | 0.1 |

|

Scope of corrosion resistance coefficient of cushion material

|

| | 质量等级 | | 适宜性描述 | | (400,+∞] | Ⅰ | 适宜 | 岩体适宜性程度高,适合作为处置岩体 | | (10,400] | Ⅱ | 基本适宜 | 岩体适宜性程度一般,需要做更深入的研究,确定是否存在其他影响适宜性因素 | | ≤10 | Ⅲ | 不适宜 | 对该岩体应采取避开策略 |

|

Evaluation standard for suitability of QHLW at tunnel scale

|

|

Schematic diagram of demonstration disposal area layout of ONKALO site

|

12]

">

|

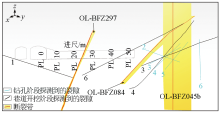

Fault zone and fracture distribution of DT1[12]

|

|

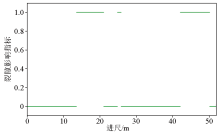

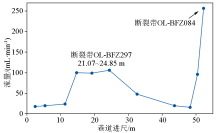

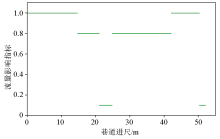

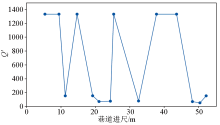

The value of the fracture influence index in DT1

|

取样深度/

m | 参数 | | TDS | pH | Cl-浓度/

(mg·L-1) | HCO3-浓度/

(mg·L-1) | SO42-浓度/

(mg·L-1) | | 422~425 | 10.54 | 7.5 | 6150 | 420 | 19 | | 488~492 | 21.2 | 7.5 | 7253 | 400 | 15 |

|

Chemical characteristics of groundwater in DT1[13]

|

14]

">

|

Permeability characteristics of rock in DT1[14]

|

|

The value of the permeability index in DT1

|

14]

">

|

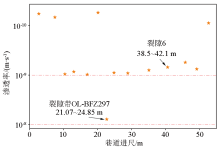

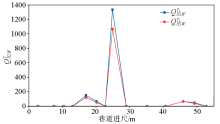

Flow distribution in DT1[14]

|

|

The value of the flow index in DT1

|

14]

">

|

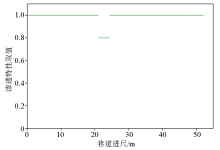

Rock mass integrity index of DT1[14]

|

|

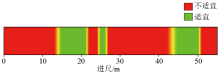

Suitability evaluation results of QHLW in DT1

|

|

Suitability evaluation results of QHLW in DT1

|

2]

">

|

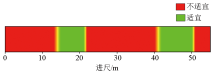

Suitability evaluation results of RSC in DT1[2]

|

|

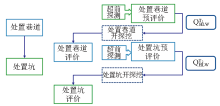

Schematic diagram of QHLW engineering evaluation system

|

18]

">

|

Schematic diagram of disposal hole layout of DT1[18]

|

| [1] |

IEAE. Scientific and technical basis for the geological disposal of radioactive wastes[R]. Vienna: International Atomic Energy Agency, 2003.

|

| [2] |

Mcewen T, Mattila J, Askokä P. Rock suitability classification-RSC[R]. Olkiluoto: Posiva Oy, 2012.

|

| [3] |

Chen L, Wang J, Liu J. A new rock mass classification system QHLW for high-level radioactive waste disposal[J]. Engineering Geology, 2015, 190:33-51.

|

| [4] |

陈亮, 王驹, 刘健, 等. 高放废物地质处置岩体适宜性评价方法(QHLW)及其在地下实验室选址中的应用研究[J]. 岩石力学与工程学报, 2018, 37(6):1385-1394.

|

| [4] |

Chen L, Wang J, Liu J, et al. A new system of rock suitability classification QHLW for high-level radioactive waste disposal and its application in the selection of URL site in China[J]. Chinese Journal of Rock Mechanics and Engineering, 2018, 37(6):1385-1394.

|

| [5] |

Heta L. Terminology report respect distance:The use of the term respect distance in Posiva and SKB[R]. Olkiluoto: Posiva Oy, 2007.

|

| [6] |

刘亦亨. 高放废物处置库巷道尺度岩体适宜性评价方法(Q_(HLW))研究[D]. 北京: 核工业北京地质研究院, 2019.

|

| [6] |

Liu Y H. Study on the evaluation method of roadway-scale rock mass suitability (Q_(HLW)) for high level radioactive waste repository[D]. Beijing: Beijing Research Institute of Uranium Geology, 2019.

|

| [7] |

Kierar I. Safety assessment report[R]. Wettingen:Nagra, 1994.

|

| [8] |

Munier R, Hokmark H. Respect distances-rationale and means of computation[R]. Stockholm: Swedish Nuclear Fuel and Waste Management Co(SKB), 2004.

|

| [9] |

Äikäs S B, Pete A. Exploring conditioned simulations of discrete fracture networks in support of hydraulic acceptance of deposition holes[R]. Olkiluoto: Posiva Oy, 2018.

|

| [10] |

Barton N, Lien R, Lunde J. Engineering classification of rock masses for the design of tunnel support[J]. Rock Mechanics, 1974, 6(4):189-236.

|

| [11] |

Anna R, Ilkka L S M, Paula K. Design and construction of equipmentand experimental deposition holes in ONKALO demonstration tunnel 1[R]. Olkiluoto: Posiva Oy, 2017.

|

| [12] |

Salminen P. Geometrical and mechanical properties of the fractures and brittle deformation zones based on the ONKALO tunnel mapping the shafts and the demonstration tunnels[R]. Olkiluoto: Posiva Oy, 2015.

|

| [13] |

Nina P, Eliisa H, Ylä-Mella M. Groundwater sampling at Olkiluoto,Eurajoki from the borehole OL-KR6 during a long-term pumping test in 2004[R]. Olkiluoto: Posiva Oy, 2006.

|

| [14] |

Komulainen J, Pekkanen J. Difference flow measurements and hydraulic interference test in ONKALO at Olkiluoto drill holes ONK-PH16 and ONK-PH17[R]. Eurajoki: Posiva Oy, 2012.

|

| [15] |

Hakala M. In situ stress measurements in ONKALO with LVDT-Cell[R]. Olkiluoto: Posiva Oy, 2017.

|

| [16] |

Kärnbränslehantering S. Detailed site investigation programme for the construction and operation of the repository for spent nuclear fuel[R]. Olkiluoto: Posiva Oy, 2018.

|

| [17] |

KÄrnbrÄnslehantering S. The integrated sulfide project-Summary Report[R]. Olkiluoto: Posiva Oy, 2019.

|

| [18] |

Markström I SKA. Rock visualization system[R]. Olkiluoto: Posiva Oy, 2015.

|

| [1] |

MA Ming-Qing, CHEN Liang, WANG Ju, LI Xiao-Jun, ZHANG Zhi-Wei, LING Hui. Design and application of the dynamic management system for scientific data of the Beishan underground research laboratory[J]. Geophysical and Geochemical Exploration, 2024, 48(6): 1559-1567. |

| [2] |

LUO Hui, CHENG Wei-Ming, ZHOU Zhi-Chao, LIU Jian, LI Ya-Wei, TIAN Xiao, YUN Long. Investigation and suitability study of pre-selected sites for geological disposal of high level radioactive waste[J]. Geophysical and Geochemical Exploration, 2023, 47(6): 1479-1489. |

|

|

|

|