|

|

|

| Study on avoidance distance between deposition hole and water conducting fracture |

LING Hui1,2( ), LI Ya-Wei1,2, CHEN Wei-Ming1,2 ), LI Ya-Wei1,2, CHEN Wei-Ming1,2 |

1. Beijing Research Institute of Uranium Geology,Beijing 100029,China

2. CAEA Innovation Center for Geological Disposal of High-level Radioactive Waste,Beijing 100029,China |

|

|

|

|

Abstract The definition of avoidance distance between deposition hole and water conducting fracture is an important basis for evaluating the site suitability of the high-level waste disposal repository,and it is also one of the key contents of the design of high-level waste disposal repository. In this paper, the site of the Beishan underground research laboratory is taken as the reference site for geological disposal of high-level radioactive waste. This paper established a computational model for the release and migration of radionuclides after closure of repository by GoldSim. Then, the avoidance distance between deposition hole and water conducting fracture in intact rock was analyzed by the method of Monte Carlo stochastic simulation. The results show that a 80% hydraulic conductivity value of the granite in the study area is less than 1.0×10-9 m/s under the existing conditions, and when the hydraulic conductivity value of water conduction fracture is set to 1.0×10-6 m/s, the corresponding avoidance distance is less than 0.5 m. The smaller the permeability coefficient is, the smaller the corresponding safety avoidance distance is. The analysis of the results shows that the avoidance distance between the deposition hole and water conducting fracture can provide a feedback guidance for the site selection and design of the disposal repository.

|

|

Received: 28 January 2024

Published: 08 January 2025

|

|

|

|

|

|

|

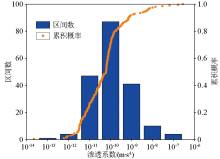

Hydraulic conductivity distribution of intact rock at a depth of 200~600 m

|

|

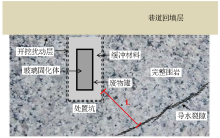

The avoidance distance between deposition hole and water conducting fracture

|

|

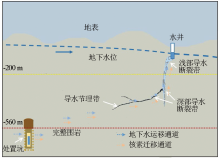

Schematic diagram of migration path of nuclide release under expected evolution scenario

|

| 国家 | 处置废物 | 处置围岩 | 剂量约束值/(mSv·a-1) | | 瑞典 | 乏燃料 | 花岗岩 | 0.014 | | 芬兰 | 乏燃料 | 花岗岩 | 0.1 | | 加拿大 | 乏燃料 | 花岗岩 | 0.3 | | 日本 | 玻璃固化体 | 花岗岩 | 0.01 |

|

Summary of the safety indicator for the countries which use granite as bedrock

|

|

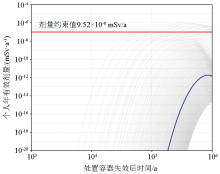

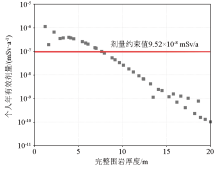

Sensitivity analysis of individual dose with the thickness of intact rock

|

|

The individual dose varies with the thickness of intact rock

|

渗透系数

累积概率 | 剂量约束值0.01 mSv/a时

安全避让距离/m | 剂量约束值0.25 mSv/a时

安全避让距离/m | | 95% | ≥7.96 | ≥1.62 | | 80% | ≥0.41 | ≥0.21 | | 50% | ≥0.12 | ≥0.12 |

|

Summary of the avoidance distance between deposition hole and water conducting fracture for different hydraulic conductivity of intact rock

|

| [1] |

王驹, 凌辉, 陈伟明. 高放废物地质处置库安全特性研究[J]. 中国核电, 2017, 10(2):270-278.

|

| [1] |

Wang J, Ling H, Chen W M. Study on the safety functions of repository for geological disposal of high level radioactive waste[J]. China Nuclear Power, 2017, 10(2):270-278.

|

| [2] |

Wang J, Chen L, Su R, et al. The Beishan underground research laboratory for geological disposal of high-level radioactive waste in China:Planning,site selection,site characterization and in situ tests[J]. Journal of Rock Mechanics and Geotechnical Engineering, 2018, 10(3):411-435.

|

| [3] |

SKB. Long-term safety for the final repository for spent nuclear fuel at forsmark,main report of the SR-Site project,SKB report TR-11-01[R]. Stockholm: Svensk Kärnbränslehantering AB, 2011.

|

| [4] |

POSIVA. Safety case for the disposal of spent nuclear fuel at Olkiluoto-Synhesis 2012,POSIVA 2012-12[R]. Eurajoki,Finland:Posiva Oy, 2012.

|

| [5] |

NWMO. Post-closure safety assessment of a used fuel repository in crystalline rock[R]. Canada:Toronto, 2012.

|

| [6] |

Technology Management Division. H12:Project to establish the scientific and technical basis for HLW disposal in Japan,Supporting Report 3:Safety assessment of the geological disposal system[R]. Ibraki: Japan Nuclear Cycle Development Institute, 2000:V19-V92.

|

| [7] |

中华人民共和国住房和城乡建设部. GB/T 50218—2014工程岩体分级标准[S]. 北京: 中国计划出版社, 2015.

|

| [7] |

Ministry of Housing and Urban-Rural Development of the People’s Republic of China. GB/T 50218—2014 Standard for engineering classification of rock mass[S]. Beijing: China Planning Press, 2015.

|

| [8] |

王驹, 苏锐, 陈亮, 等. 中国高放废物地质处置地下实验室场址筛选[J]. 世界核地质科学, 2022, 39(1):1-13.

|

| [8] |

Wang J, Su R, Chen L, et al. Site selection of underground research laboratory for geological disposal of high-level radioactive waste in China[J]. World Nuclear Geoscience, 2022, 39(1):1-13.

|

| [9] |

季瑞利, 张明, 周志超, 等. 北山预选区钻孔水文地质试验方法研究[J]. 铀矿地质, 2018, 34(1):53-59.

|

| [9] |

Ji R L, Zhang M, Zhou Z C, et al. Research on in situ hydraulic test method in Beishan pre-selected area[J]. Uranium Geology, 2018, 34(1):53-59.

|

| [10] |

EPRI. Evaluation of the proposed high-level radioactive waste repository at Yucca Mountain using total system performance assessment,Phase 6,Technical Report 1003031[R]. California:Electric Power Research Institute,Palo Alto, 2002.

|

| [11] |

刘月妙, 王驹, 曹胜飞, 等. 中国高放废物地质处置缓冲材料大型试验台架和热—水—力—化学耦合性能研究[J]. 岩土力学, 2013, 34(10):2756-2762,2789.

|

| [11] |

Liu Y M, Wang J, Cao S F, et al. A large-scale THMC experiment of buffer material for geological disposal of high level radioactive waste in China[J]. Rock and Soil Mechanics, 2013, 34(10):2756-2762,2789.

|

| [12] |

陈伟明. 高放废物地质处置库系统分析方法研究——以甘肃北山预选区花岗岩场址为例[D]. 北京: 核工业北京地质研究院, 2008.

|

| [12] |

Chen W M. Study on systematic analysis method of geological disposal repository of high level radioactive waste—A case study of granite site in Beishan pre-selection area of Gansu Province[D]. Beijing: Beijing Research Institute of Uranium Geology, 2008.

|

| [13] |

IAEA. Reference biospheres for solid radioactive waste disposal,International Atomic Energy Agency,IAEA-BIOMASS-6[R]. Vienna:IAEA, 2003.

|

| [1] |

LUO Hui, CHEN Wei-Ming, LI Ya-Wei, TIAN Xiao, ZHANG Jing-Jia. Study on deep geological environmental characteristics of the Shazaoyuan area[J]. Geophysical and Geochemical Exploration, 2024, 48(6): 1568-1576. |

| [2] |

YUN Long, CHEN Su, FU Lei, ZHUANG Hai-Yang, WANG Ju. Seismic response characteristics of the cavern group of the Beishan underground research laboratory for the geological disposal of high-level radioactive waste[J]. Geophysical and Geochemical Exploration, 2024, 48(6): 1519-1529. |

|

|

|

|