|

|

|

| A study of the application parameters of cement ring in oil hole cement in the correction of gamma retargeting coefficient |

LI Xiao-Wei1( ), ZANG Yong-Liang2( ), ZANG Yong-Liang2( ), LUO Ning3, LI Ming2, DOU Ke2 ), LUO Ning3, LI Ming2, DOU Ke2 |

1. Sino Shaanxi Nuclear Industry Group Geological Survey Co.,Ltd., Xi’an 710100,China

2. Erlian Branch of Petro China Huabei Oilfield Company, Xilin Hot 026099,China

3. Petro China Huabei Oilfield Company,Renqiu 062552,China |

|

|

|

|

Abstract The gamma retest of the old well in the oil hole is an economical and practical method to measure the radioactivity by FD-3019 probe tube when the oil well maintenance team takes out the sucker rod. Due to the influence of cementing cement ring in oil drilling on gamma logging results, the current gamma logging code has only the correction of molten iron coefficient but no correction of absorption attenuation of cement ring. Therefore, gamma reiteration data can be used to appraise drill radioactive anomaly correctly through the cement ring attribute parameter correction. It is concluded that the main influence parameters of cementing cement ring are cement ring density and cement ring thickness. By making a number of cement ring model holes with different thickness and density, simulating down hole conditions, establishing models and using different model cement ring absorption coefficient values, the authors finally found out the influence coefficient of cementing cement ring on gamma logging illumination rate and carried out correction and demonstration experiments to make the revised data infinitely close to the true formation value. Combined with the actual data of an oil field block in Inner Mongolia, the authors revised the data through the modified coefficient of cement ring experimental logging and discussed the relationship between the density, thickness of cement ring and the irradiation rate. The feasibility of the method is validated by verifying hole technology. The result provides the correction basis for guiding the results of the next re-survey of old oil wells.

|

|

Received: 01 July 2020

Published: 27 July 2021

|

|

|

|

Corresponding Authors:

ZANG Yong-Liang

E-mail: xiaowei3377@163.com;el_zangyongliang@petrochina.com.cn

|

|

|

|

|

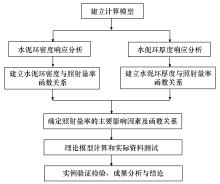

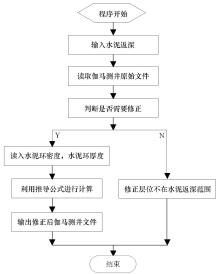

The diagram of experimental flow of cement ring

|

|

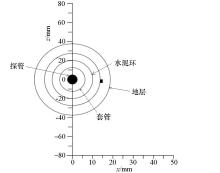

The schematic diagram of calculation model of cement ring

|

模型

序号 | 模型

井名 | 套管规格 | 水泥环密度/

(g·cm-3) | 水泥环厚度/

mm | | 模型一 | ZK-PVC | N80-139.7-7.72 | 无 | 无 | | 模型二 | ZKSM1 | N80-139.7-7.72 | 1.63 | 26.15 | | 模型三 | ZKSM2 | N80-139.7-7.72 | 1.72 | 26.15 | | 模型四 | ZKSM3 | N80-139.7-7.72 | 1.82 | 26.15 | | 模型五 | ZKSM4 | N80-139.7-7.72 | 1.94 | 26.15 |

|

Parameters of cement ring density response model

|

模型

序号 | 模型

井名 | 套管规格 | 水泥环密度/

(g·cm-3) | 水泥环厚度/

mm | | 模型一 | ZKPVC | N80-139.7-7.72 | 无 | 无 | | 模型六 | ZKSH1 | N80-139.7-7.72 | 1.82 | 6.15 | | 模型七 | ZKSH2 | N80-139.7-7.72 | 1.82 | 55.15 | | 模型八 | ZKSH3 | N80-139.7-7.72 | 1.82 | 20.00 | | 模型九 | ZKSH4 | N80-139.7-7.72 | 1.82 | 26.15 |

|

Response model parameters of cement ring thickness

|

| 序号 | 模型

井名 | 套管规格 | 水泥环密度/

(g·cm-3) | 水泥环厚度/

mm | | 模型十 | ZBK1 | N80-139.7-7.72 | 1.51 | 58.15 | | 模型十一 | ZBK2 | N80-139.7-7.72 | 1.92 | 14.65 | | 模型十二 | ZBK3 | N80-139.7-7.72 | 1.76 | 38.15 | | 模型十三 | ZBK4 | N80-139.7-7.72 | 1.88 | 44.35 |

|

Response model parameters of density — thickness of cement ring

|

|

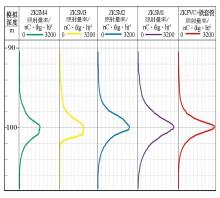

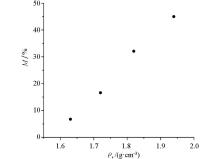

The relationship diagram between cement ring density and exposure rate

|

|

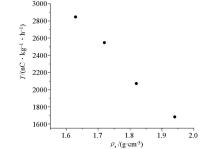

The scatter diagram of the relationship between peak density of cement ring and exposure rate

|

| 模型 | R | R方 | 调整后R方 | 标准估算

的误差 | 德宾—沃森 | | 1 | 0.997a | 0.995 | 0.992 | 46.26180 | 3.351 | | a预测变量:(常量), 密度;b因变量:照射量率 |

|

Model summary table

|

| 模型 | 未标准化系数 | 标准化系数 | t | 显著性 | | B | 标准误差 | Beta | | 1 | (常量) | 9130.395 | 357.013 | | 25.574 | 0.002 | | 密度 | -3850.745 | 200.429 | -0.997 | -19.213 | 0.003 | | a因变量:照射量率 |

|

Model coefficient table

|

|

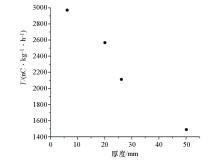

The scatter diagram of relation between the density of different cement ring and absorption coefficient

|

|

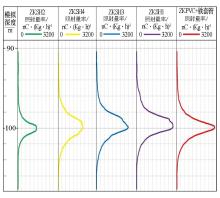

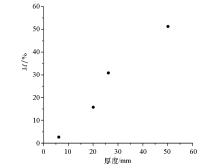

The diagram of relationship between cement ring thickness and exposure rate

|

|

The scatter diagram of relationship between peak thickness of cement ring and exposure rate

|

| 模型 | 未标准化系数 | 标准化系数 | t | 显著性 | | B | 标准误差 | Beta | | 1 | (常量) | 3093.659 | 145.447 | | 21.270 | 0.002 | | 厚度 | -30.157 | 4.508 | -0.978 | -6.689 | 0.022 | | a因变量:照射量率 |

|

Model coefficient table

|

|

The scatter diagram of relation between the thickness of different cement ring and absorption coefficient

|

|

The flow chart of gamma-ray retest coefficient correction program

|

|

The program interface of coefficient correction

|

| 名称 | 规格/mm | 壁厚/mm | 内径/mm | 下入深度/m | 水泥返深/m | 水泥浆密度/

(g·cm-3) | 水泥浆厚度/mm | | 表层套管 | 339.7 | 9.73 | 320.24 | 56 | 4 | 1.82 | 38.15 | | 油层套管 | 139.7 | 7.72 | 124.26 | 1291.6 | 325 | 1.88 | 38.15 |

|

Statistics of casing and cement slurry data

|

|

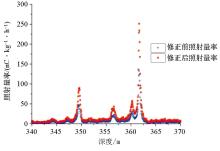

The scatter diagram of comparison before and after ZKM correction

|

|

The comparison diagram of verification hole curve before and after ZKM correction

|

钻孔

编号 | 矿段位置/m | 厚度/m | 品位/% | 平米铀量/

(kg·m-2) | 边界品位/% | 评价结果 | | 自 | 至 | 未修正前石油老井

复测结果 | 360.35 | 361.25 | 0.90 | 0.0070 | 0.13 | 0.005 | 异常层 | | 361.25 | 362.05 | 0.80 | 0.0322 | 0.51 | 0.01 | 矿化层 | | 362.05 | 362.45 | 0.40 | 0.0067 | 0.05 | 0.005 | 异常层 | | 修正后复测结果 | 360.85 | 362.45 | 1.60 | 0.0342 | 1.0928 | 0.01 | 工业层 | | 验证孔解释结果 | 365.15 | 366.65 | 1.50 | 0.0361 | 1.08 | 0.01 | 工业层 |

|

Comparison of the hole interpretation results before and after correction

|

| [1] |

张云怡. 辽河油田勘探钻井投资效益评价研究[D]. 大连:大连理工大学, 2009.

|

| [1] |

Zhang Y Y. The research and evaluation of exploration and drilling investment economic benefits in Liaohe oilfield[D]. Dalian:Dalian University of Technology, 2009.

|

| [2] |

闻国峰, 钟水清, 陈武, 等. 油气勘探效益评价指标体系及方法研究[J]. 钻采工艺, 2005(3):40-42.

|

| [2] |

Wen G F, Zhong S Q, Chen W, et al. Evaluation index system and method for oil and gas exploration benefit[J]. Drilling and Production Technology, 2005(3):40-42.

|

| [3] |

张森, 石蕾, 鞠楠, 等. “油铀兼探”的找矿思路在松辽盆地的应用——以中央拗陷区南部为例[J]. 地质与资源, 2018(3):257-262.

|

| [3] |

Zhang S, Shi L, Ju N, et al. The“oil-uranium co-exploration”idea in Songliao basin:A practice in southern central depression[J]. Geology and Resources, 2018(3):257-262.

|

| [4] |

黄隆基. 放射性测井原理[M]. 北京: 石油工业出版, 1985:81-99.

|

| [4] |

Huang L J. Principle of radioactive logging[M]. Beijing: Petroleum Industry Publishing: 1985,81-99.

|

| [5] |

程业勋, 王南萍, 侯胜利, 等. 核辐射场与放射性勘查[M]. 北京: 地质出版社, 2005:88-96.

|

| [5] |

Cheng Y X, Wang N P, Hou S L, et al. Nuclear radiation field and radioactive exploration[M]. Beijing: Geological Publishing House, 2005:88-96.

|

| [6] |

宋明, 杨风香, 宋胜利, 等. 固井水泥环对套管承载能力的影响规律[J]. 石油钻采工艺, 2002, 24(4):7-9.

|

| [6] |

Song M, Yang F X, Song S L, et al. Influencing tendencies of cement sheath on casing carrying capacity[J]. Oil Drilling and Production Technology, 2002, 24(4):7-9.

|

| [7] |

李勇, 刘硕琼, 王兆会, 等. 水泥环厚度及力学参数对其应力的影响[J]. 石油钻采工艺, 2010, 32(4):37-40.

|

| [7] |

Li Y, Liu S Q, Wang Z H, et al. Effect of cement thickness and its mechanical parameters an cement Stress[J]. Oil Drilling and Production Technology, 2010, 32(4):37-40.

|

| [8] |

邓小卫, 赵军辉. 测井资料自动化处理解释系统应用研究[R]. 核工业203研究所, 2005.

|

| [8] |

Deng X W, Zhao J H. The study on the applicationof automatic processing and interpretation system for logging data[R]. 203 Research Institute of nuclear industry, 2005.

|

| [9] |

吴文圣, 肖立志. 套管井中补偿密度测井响应特性的Monte Carlo数值模拟[J]. 中国石油大学学报:自然科学版, 2007, 31(1):45-48.

|

| [9] |

Wu W S, Xiao L Z. Monte Carlo numerical simulation of response characteristics of compensated density logging in cased hole[J]. Journal of China University of Petroleum:Edition of Natural Science, 2007, 31(1):45-48.

|

| [10] |

吴文圣. Monte Carlo方法在核测井中的新应用[J]. 测井技术, 2001, 25(6):412-416.

|

| [10] |

Wu W S. New application of Monte Carlo method in nuclear logging[J]. Logging Technology, 2001, 25(6):412-416.

|

| [11] |

郭荣坤, 王贵文. 测井地质学[M]. 北京: 石油大学出版社, 2000.

|

| [11] |

Guo R K, Wang G W. Well logging geology[M]. Beijing: Petroleum University Press, 2000.

|

| [1] |

ZHAO Xu-Chen, LI Xue-Jian, CAO Fang-Zhi, LEI Xiao-Dong, LI Chen, HAN Yu-Da. An analysis of the detection effect of cross-well electromagnetic wave CT in coal mine goaf[J]. Geophysical and Geochemical Exploration, 2021, 45(4): 1088-1094. |

| [2] |

SUN Mao-Rui, WANG Shuang-Liu. The application of the electromagnetic wave CT of the 2D and 3D imaging[J]. Geophysical and Geochemical Exploration, 2015, 39(3): 641-645. |

|

|

|

|